How to Make A Fine Animatronic Dinosaur

The first step is to find a reference for the dinosaur image? You can visit the museum to see the dinosaur skeletons, or you can purchase exquisite small dinosaur models, etc. By observing the appearance of dinosaur bones, we can get a general idea of the shape of their bodies. So how can we fill in the gaps regarding the skin, color and muscles of the dinosaur skeletons?

The job of sculptors and designers is to fill in the flesh and skin of the dinosaurs. To achieve this, they usually have to conduct research on the environment of dinosaurs. For instance, if dinosaurs were predators, they might have needed to move quickly. This will affect the muscle mass in the legs of the dinosaurs.

In this article, you will see how our work is carried out. Mechanics, designers, sculptors, fabricators, and others used fossil images, mechanical transmission devices, and synthetic fiber materials to reconstruct the mysterious creatures from the prehistoric era.

In this craft project, choose a dinosaur or another prehistoric species to reconstruct. Use the information of the discovered prehistoric creature to create its model. Above, you will see in a short video the workers’ rigorous works, demonstrating the necessary steps such as carving, skinning, and painting to restore a large animatronic dinosaur model.

Overview and materials of the Dinosaur Model:

First of all, you need to select a dinosaur (or another prehistoric reptile) for your project.

This project can be completed in groups of five people. Team members need to conduct a 10-15 minute research on dinosaurs and reach consensus among all departments, such as the art department, mechanical department, electrical department, etc.

QUICK FACTS:

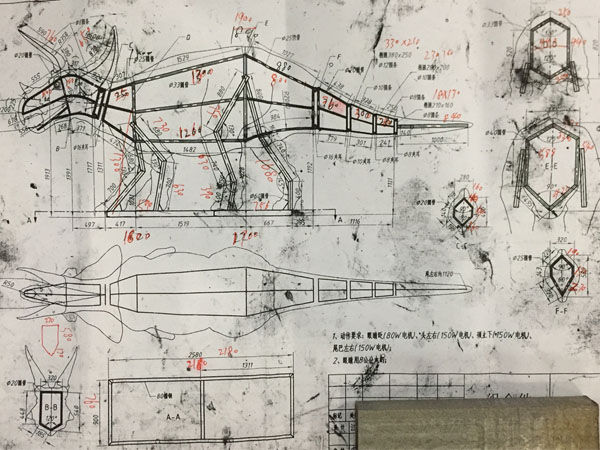

#1. Drawing of mechanical and motor structures

#2. Constructing the internal frameworks

#3. Wrapping sponge / foam on the frameworks

#4. Sculpting dinosaur outline on the foam / sponge

#5. Manufacturing skin texture works

#6. Creating lifelike skin

#7. Dyeing and spray painting skin colors

#8. Inspecting electric appliance running

1. Drawing of mechanical and motor structures

- Draw the dinosaur outline on an A4 sheet of paper.

- And mark the outline sectional diagrams and the dimensions.

Required materials and tools:

- One A4-sized sheet of paper

- One pencil

- One eraser

- One computer (optional)

Use computer to work diagram::

On your computer, use the PS technology to create a dinosaur’s body sketch. Draw the dinosaur from top, bottom, side, front and rear views. Even more rigorously, it is possible to create a three-dimensional spatial dinosaur model. It can also indicate the dinosaur characteristics, such as whether it had flat head, spines, long arms, etc. For each feature, provide a brief description so that the workers can consider it more thoroughly during the production process.

2. Constructing the internal frameworks

(1). Based on the marked dimensions, cross-sectional diagrams and external features, the steel pipes / frames are welded together to form the dinosaur mechanical frameworks.

(2). Leave the position for mechanical transmission and install the motor properly. (At different locations, the motor power rating varies; based on the force required in that area, a motor with a higher power rating should be used)

(3). After the mechanic completed the fabrication and motor frameworks installation, he applied industrial grease at the transmission points and installed springs (to reduce the large impact force caused by the motor’s operation).

Required materials and tools:

- National standard steel (steel pipes + channel steel)

- Wiper industrial motors

- Mold reducers

- Industrial butter

- Springs

- Welding machine

- Electrode holder

- Welding rod

The quantity of the above materials and tools is determined by the dinosaur model size. Fabricating a 5 meters long Tyrannosaurus Rex model, required 250 kilograms of steel, 7 motors (150W – 250W), 1 reducer, 100 grams of industrial butter, 3 springs, 2 welding machines with a power of 1000W, 3 welding pliers and 20 welding rods.

3. Wrapping sponge / foam on the frameworks

- Wrap and attach a 5 centimeters thick sponge / foam layer all over the mechanical framework

- Attach 7 centimeters thick, 3-centimeters thick and 10 centimeters thick sponge respectively to the legs, claws and head of the dinosaur (to fill in larger shapes)

Required materials and tools:

- 3cm / 5cm / 7cm / 10cm thick sponge

- Universal glue (yellow glue – adhesive)

- Long knife (for cutting sponge)

- Brush (dipped in yellow glue)

Manufacturing a 5 meters long Tyrannosaurus Rex model, required 5 pieces of sponge as 1.5 meters × 3 meters (10cm thick 2 pieces, 7cm thick 1 piece, 5cm thick 1 piece, 3cm thick 1 piece), 10 kilograms (1 bucket) of yellow glue, 3 long knives, 3 brushes.

4. Sculpting dinosaur outline on the foam / sponge

- Use a long knife to carve out the dinosaur’s appearance outline (the head, the mouth, the claws, the tail, etc.).

- Use a knife to carve out the dinosaur’s claws and footpaws one by one, and then attach them.

Required materials and tools:

- A 10 centimeters thick sponge

- Universal glue (yellow glue – adhesive)

- Long knife (carving sponge)

- Short knife (carving sponge)

Building a 5 meters long Tyrannosaurus Rex model, Required 1/3 piece of sponge as 1.5 meters × 3 meters, 10 centimeters thick, 50 grams of yellow glue.

5. Manufacturing skin texture works

- On the shaped sponge, carefully outline and stamp the skin texture of the dinosaur (usually in the form of round dots or tree bark patterns).

Required materials and tools:

- Electric soldering iron (slightly thicker with prominent grooves)

- Electric soldering pen (fine skin lines)

Manufacturing a 5 meters long Tyrannosaurus Rex model, required 1 electric soldering iron, 2 electric soldering pens.

6. Creating lifelike skin

- Apply a uniform layer of silicone sealant over the prepared sponge textures.

- Before the silicone gel dries, carefully attach a layer of stockings to it.

- Apply two even layers of silicone.

- Then a layer of the mixture of gasoline and silicone was applied, making the Muscle Skin smooth.

Required materials and tools:

- Silicone adhesive

- Gasoline

- Silk stockings

- Scraper

- Glue gun

- Hairbrush

Manufacturing a 5 meters long Tyrannosaurus Rex model, required 24 tubes of silicone, 5 kilograms of gasoline, 50 pairs of stockings, 3 knives, 2 glue guns and 2 hairbrushes.

7. Dyeing and spray painting skin colors

(1). Mix oil paints, gasoline and silicone in a basin.

(2). Pour the mixed substance into the pot of the spray gun (before pouring, attach a layer of stockings over the spout of the pot, so that the paint residue can be effectively filtered during the pouring process).

(3). Connect the air tube (spray gun and air compressor).

(4). Paint the various parts of the dinosaur’s body with colors based on the actual skin tones of real dinosaurs.

Required materials and tools:

- Silicone adhesive

- Gasoline

- Silk stockings

- Oil color

- Basin

- Spray gun

- Air compressor

- PU tube

Building a 5 meters long Tyrannosaurus Rex model, required 10 tubes of silicone glue, 3 kilograms of gasoline, 1 pair of stockings, 8-10 tubes of oil paints, 1 water basin, 1 spray gun, 1 air compressor and 10 meters long PU tube.

NOTIFICATION: The dyeing skin works is meticulous and complex, and it can only be accomplished by skilled and experienced painters. The combination of materials and colors is also based on years of experience. Ultimately, the realism achieved of an animatronic dinosaur depends largely on the painting works quality, which accounts for at least 50% of the total importance.

8. Inspecting electric appliance running

- Place the completed CPU control box beside the dinosaur’s legs.

- Connect the cables between the dinosaur and the control box.

- Turn on the power supply of the control box and test whether the movement and roar of the dinosaur are smooth.

- Utilize the entire working day to continuously have the dinosaur moves (for testing), so as to ensure that there are no electrical faults before they are put on the market.

Conclusion

This post describes our rigorous and detailed animatronic dinosaur production. After reading this article, you should have a basic understanding of our dinosaurs value. Surely, we also can customize any dinosaur species through above 8 manufacturing steps.

After watching the above production video and reading the detailed steps for making fine animatronic dinosaur model, you will have a very clear understanding of our working process. We welcome potential customers to contact us to learn more details.

Leave a Reply